Optimize Your Manufacturing Performance in 2022

Table of Contents

Vertical Drop Lifts

The Problem

Vertical Drop Lifts (VDL) are one of the most common place assets in an automotive assembly plants. As most automotive plants are crowded and have limited space to move, VDLs give plants the ability to safety raise and lower car bodies for transportation above or below the shop floor.

This asset is crucial to plant operations and its failure often leads to line shutdowns and significant production losses.

Cost of Asset Failures

- $7400/hour downtime cost

- 1.5 hours downtime, on average

- Significant production losses

Savings Potential

- $11,100 per asset

- $77,700 per plant (based on estimated asset count)

Asset Blind Spots

There are several inherent challenges related to monitoring vertical drive lifts.

Vibration frequencies are often undetectable to the human ear and eye, especially given the number of different components where issues could arise (e.g. motor, gearbox, bearings).

Time-based PMs and other checks are not thorough enough to ensure that no failures will occur.

A New Approach to Vertical Drop Lifts

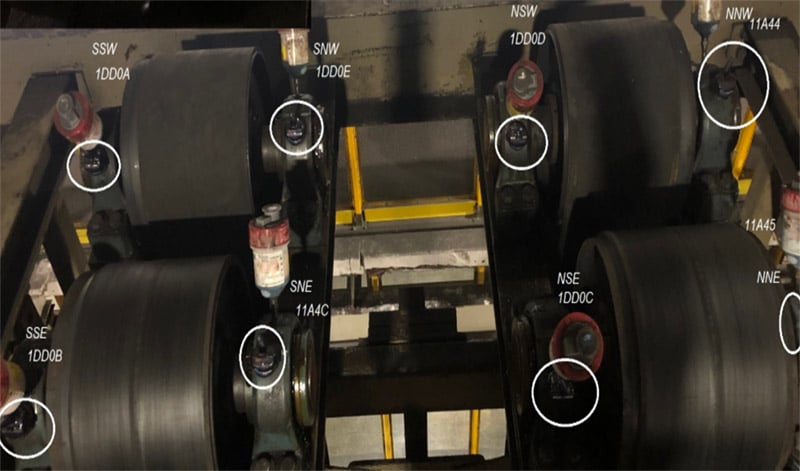

The best way to monitor VDLs is using the IoT Hub. The IoT hub offers the unique feature of triggering which is important when taking readings on an intermittent asset – such as a lift. Triggering with the Hub not only allows us to capture whatever part of the lifts motion we want, but also allows us to take repeatable readings for accurate health comparisons. Our IoT Hub even offers the option to connect with existing embedded sensors using an adapter so that all data can be historically saved in our cloud based platform.

Hardware

- 1-2 IoT Hubs per VDL

Software

- Set thresholds and indicators after collecting sample data

Customer Inputs

No additional information needed

Training

- Sentry bi-annual site visits

- Sentry in-person training

- KCF Academy

- Customer training and playbooks

I am excited to drive change in partnership with you, find new efficiencies, take on complex challenges, and increase uptime across the Ford network while making your team's work life more engaging and fulfilling. Please contact me to discuss your unique asset challenges!