Optimize Your Manufacturing Performance in 2022

Table of Contents

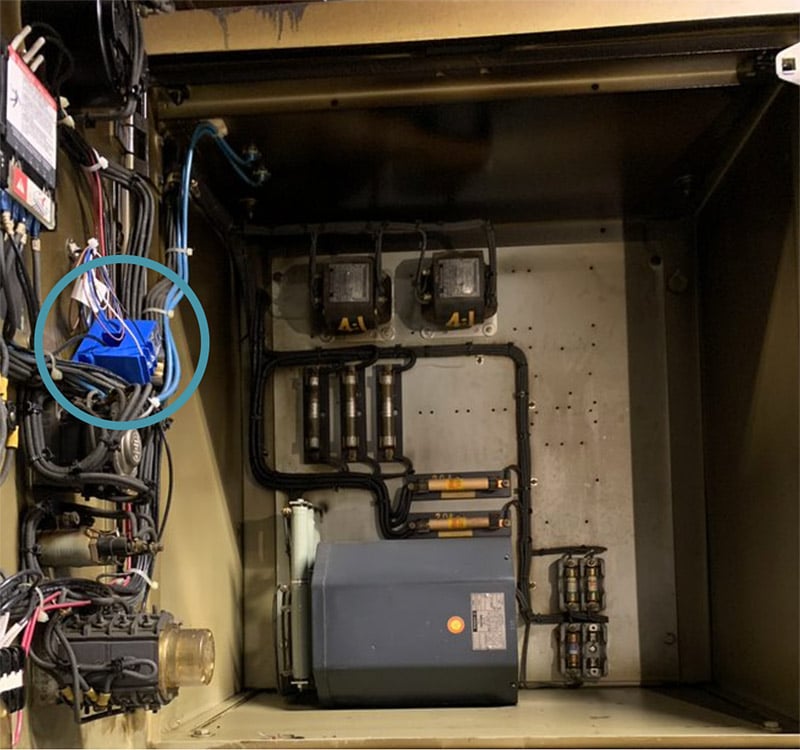

Lubrication Skid Pump

The Problem

A Lubrication Skid is a piece of lubrication equipment used to top off oils, greases, or other fluids for machinery. They reduce the need for oil storage lockers, barrels, and containers, which can be challenging to maintain. This asset is essential to monitor because it is crucial to plant operations and could lead to serious downtime, as replacement parts can take a long to arrive.

Cost of Asset Failures

- ~$900K/hour downtime cost

- 3 hours downtime, on average

Savings Potential

- $3,601,878 per asset

- $14,407,512 plant wide (based on estimated asset count)

Asset Blind Spots

There are several inherent challenges related to monitoring power distribution and energy consumption.

Difficult for the human ear/eye to detect vibration frequencies.

Typical route based PMs for lubrication degradation does not capture the fully life of lubrication and can lead to false conclusions

Waiting for audible/visual queues to problems can often be too late for a simple fix in the failure

A New Approach to Lubrication Skid Pumps

A HUB would be the optimal solution for monitoring lubrication skids as it allows for the deployment of both vibration and ultrasonic monitoring from one device. Ultrasonic is a great early indication of lubrication issues and vibration can help to pinpoint the cause of these problems or areas that lubrication degradation could be impacting more than others. The HUB also offers the unique solution of triggered measurements for lubrication skids that may not run as frequently as others.

Hardware

- V3 Sensors on MIB and both Pumps on each Lubrication Skid.

- IoT Hub could also supplement these sensors and enable Ultrasonic Monitoring

Software

- Set thresholds and other indicators after collecting sample data. This will alert us when the vibration increases as problems arise.

Customer Inputs

- No additional customer input needed

Training

- Sentry

- Site visits 2 times/year

- In-person training

- Academy

- Customer training/handbooks

- Asset Playbook

I am excited to drive change in partnership with you, find new efficiencies, take on complex challenges, and increase uptime across the Ford network while making your team's work life more engaging and fulfilling. Please contact me to discuss your unique asset challenges!